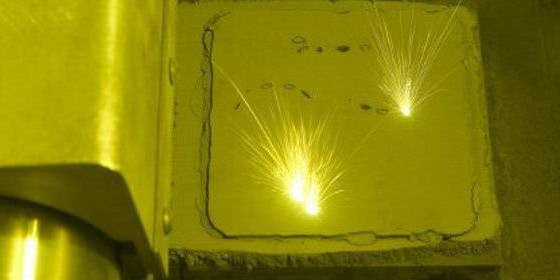

AMS uses Direct Metal Printing Technology

We use Direct Metal Printing (DMP) to produce high quality, metal dental prostheses at high speed. Using our print service Dental Laboratories can now eliminate various steps and substantially reduce unit cost per partial, while maintaining or increasing quality. With its certified Ni-free CoCr materials for dental use.

Best surface finish, less supports

With a surface finish quality of up to 5 Ra μm less post-processing is required and sharpest corner radiuses are achieved. Due to the proprietary powder deposition system, the ProX DMP builds down to 20° angles without supports. All overhanging surfaces benefit from this much better surface quality compared to competing machines. Less supports and improved surface quality ultimately mean less post processing – saving time and cost.

Outstanding accuracy for the perfect fit

The typical accuracy is +/- 50 μm (+/- 0.002 inches), allowing a perfect fit for every patient. Repeatability from part to part is approximately 20 μm (0.0008 inches).

Fully dense parts with fine detail and thinnest walls

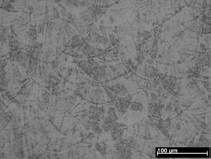

Due to 3D Systems’ patented layer compaction technology, the ProX DMP printers produce fully dense partials, crowns and bridges, eliminating the porosity you can find with casting processes. The patented technology also allows using smaller particles, which in turn helps to generate finest feature detail available in the market and thinnest possible wall thicknesses.

Material

Cobalt Chrome alloy with 0% Nickel.

Ni free alloy chemical composition is suitable for biomedical applications. The alloy powder is CE certified.

S & S Scheftner GmbH Modelstar S Powder, Material Data Sheet

CoCr part microstructure after

recommended heat treatment

Chemical Composition

|

Chromium |

28.5% |

|

Cobalt |

62.5% |

|

Molybdenum |

6% |

|

Manganese, Silicon, Iron, Carbon |

3.00% each <1.00% |

|

Nickel |

0% |

Mechanical Properties

|

Tensile Strength, (Rm) MPa |

1220 |

|

Yield Strength, (Rp0.2) MPa |

730 |

|

Elongation at break, (A5) % |

20 |

|

Hardness, HV10 |

385 |

|

Density, g/cm3 |

8.3 |

|

Modulus of elasticity, GPA |

200 |

|

Solidus Liquidus Interval, °C |

1310-1410 |

|

Thermal expansion (25-500°C), 10-6/K-1 |

14.5 |