Dental

|

|

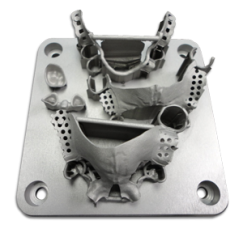

Removable Partial Denture FrameworksSingle copings and multi unit bridgesImplant abutmentsCustom bars and strengthening frames |

Laser sintered cobalt chrome is superior to a cast product.

The sintering process creates a consistent metal structure throughout the final product that cannot be achieved with casting. Laser sintered parts are near 100% dense and have no porosity and no inclusions. They are not as brittle as cast and thin structures such as clasps can be adjusted without fatigue.

Strength, dimensional accuracy and surface detail are consistently reproduced and not likely to fail as some cast products can.

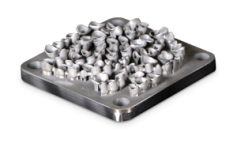

AMS uses industry leading direct metal printing (DMP) technology. DMP uses a fine grain powder that provides print detail as low as 20 micron. Other technologies using metal injection moulding (MIM) powders use particle sizes of 45-100 micron and cannot produce this level of detail.

Industry Leading Advantage

Chrome Dental Laboratories and Technicians will benefit from:

-

Eliminating steps for casting a product

-

No investment tools and materials

-

No wastage

-

- Reduce health and safety requirements with no casting fumes and less handling of material

- Able to reproduce frameworks in the case of loss or damage

-

Opportunity to move into new technology with digital design

-

Compete with overseas partial denture products

- Safe for biomedical use with certified (pdf) alloy and process

-

Provide faster turnaround of product that is of superior quality

-

Free up skilled technicians for design, finish and fitting

-

Increase total business capacity to take on more volume of work

-

Respond to your clients demands for the latest digital technology in dentistry

The process requires the dental technician to digitally design the frame and upload the file to AMS. Once printed and post processing is complete we deliver a frame that can then be polished and fitted.

Product Finishing

For partial dentures we provide two options for finishing:

- Sandblasted. The partial denture has been 3D printed, supports removed and trimmed and then sandblasted. The finishing work required is similar or less than what would be required for a cast product.

- Pre-Polish (or semi-polished). The partial denture has been 3D printed, supports removed and trimmed, surface ground with diamond tools and burrs to remove excess sintered powder. The frames are then polished in our Dlyte machine. The finishing work required is for the technician to fit to the model, fine detailing and buffing to a high polish.

Other Applications for Cobalt Chromium Alloy

- Attachments to dental implants, bars, frames, crowns, copings, bridges

- Gas turbines

- Automotive parts needing high wear and corrosion resistance

- Tool making and specialist tools

- Injection moulds

- Parts with thin walls or fine features